Centre of excellence in space tribology

The European Space Tribology Laboratory (ESTL) is Europe’s focus for expertise in space tribology. ESTL is a department of ESR Technology, a Hyder Consulting Group company, and is operated with the support of the European Space Agency (ESA).

ESTL is acknowledged as the centre of excellence in space tribology within Europe and has served ESA and the European space mechanisms community in this capacity for 40 years.

ESTL specialises in providing solutions to friction, wear and lubrication issues relating to the precision mechanisms that operate in the vacuum environment of space, or in terrestrial vacuum applications. Over the past 40 years, ESTL has been involved in virtually every major European Space programme, with no known failures in orbit.

ESTL delivers solutions by offering a flexible combination of specialist products and services:

- Tribology – we have many years of tribological data from which we have developed processes and design tools. We also provide consultancy and training

- Testing – we have years of experience performing thermal vacuum and tribometer tests and regularly undertake life, qualification and acceptance testing for our customers. ESTL is an ESA-approved test centre

- Lubrication – we provide a range of high quality and space qualified solid and liquid lubrication products

- Transfer – we transfer these specialist technologies developed for space into terrestrial vacuum markets such as the medical and semiconductor industries

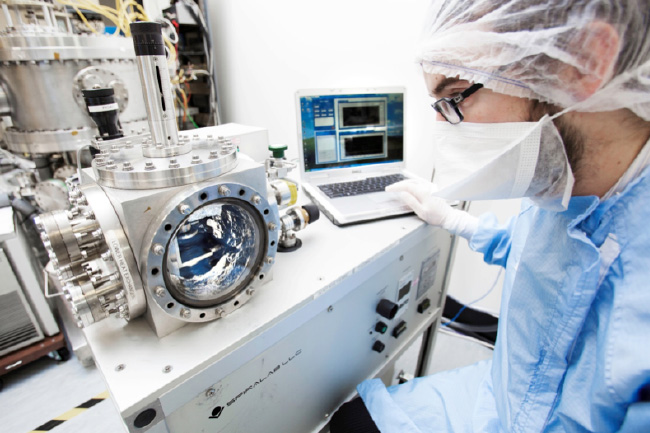

ESTL operates from a 185 m2 cleanroom, conforming to the American Federal Standard class 10,000 (M5.5). We have several tribometers, including a vacuum pin on disc tribometer and a spiral orbit tribometer (the only one of its kind in Europe) for assessing friction and wear. The cleanroom has a range of thermal vacuum test chambers, equipped with instrumentation for data acquisition and control of test items

Contact person

Dr Matthew Hampson, Project Manager

ESTL

ESR Technology

202 Cavendish Place

410 The Quadrant,

Birchwood, Warrington,

Cheshire WA3 6WU

UNITED KINGDOM

Phone: +44 (0)1925 84 3494

Email: matthew.hampson[at]esrtechnology.com

www.esrtechnology.com

Short Bio

Matthew Hampson holds a PhD in solid state chemistry and a master’s degree in chemistry, both from University of Durham, United Kingdom. Dr Hampson currently works as a project manager at ESTL, where his responsibilities include the management of research and development projects in space tribology. He has particular experience in the development of new lubricant coatings, as well as a wide range of tribological test programs. He has presented several papers on space tribology, at conferences such as ESMATS (the European Space Mechanisms and Tribology Symposium).

Dr Hampson acts as the Technical Coordinator and Management Coordinator for ESTL in the REACT consortium.

PUBLICATIONS

ESTL generates a large number of documents covering research activities funded by the European Space Agency. These are publically available in ESA member states, and may be accessed via the ESR Technology website: (http://www.esrtechnology.com/centres/estl/Pages/register.aspx).

- Some relevant documents are listed below:

- ESA-ESTL-TM-0030 Hard, High Friction Interfaces for Space Applications

- ESA-ESTL-TM-0066 Spiral Orbit Tribometer Assessment of Space Lubricants

- ESA-ESTL-TM-0096 Post-test characterisation of tribological surfaces

- “Spiral Orbit Tribometer Assessment of Space Lubricants”, Michael Buttery, 13th European Space Mechanisms and Tribology Symposium, 2009